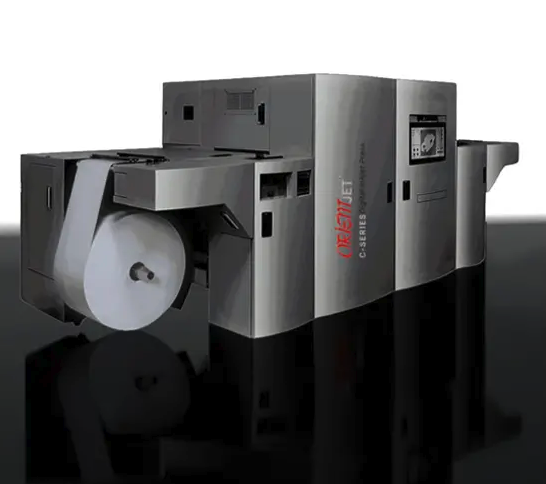

Multitec S1 Narrow Web Flexo

Description

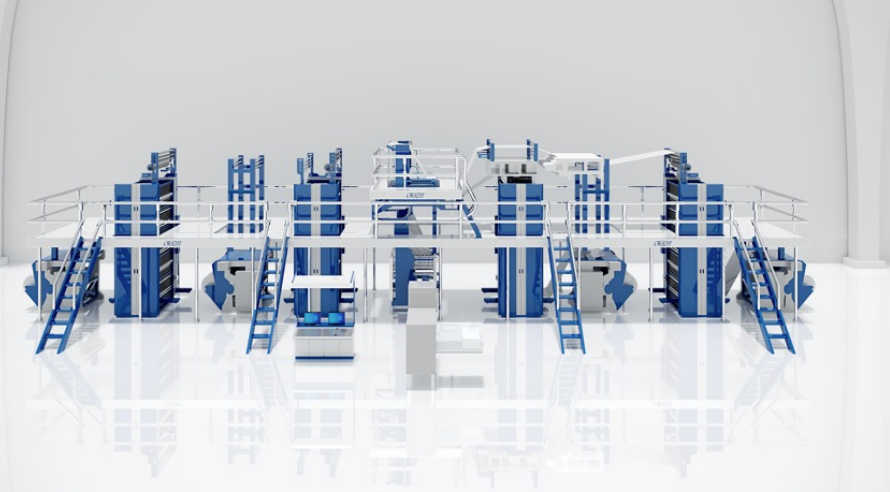

The Multitec S1 is a high-performance shaftless full servo flexographic press designed for printing on flexible packaging and self-adhesive labels. With a web width range of 370 mm to 530 mm and a maximum speed of 180 m/min, it delivers precise, high-quality printing for both short and long runs. Ideal for expanding into markets like sleeves, wrap-around labels, and pouches.

Product Details

The Multitec S1 is a state-of-the-art shaftless full servo narrow web flexographic press designed for printing on flexible packaging and self-adhesive labels. Each print unit, along with the infeed and outfeed sections, operates independently via servo drives, ensuring exceptional graphic precision and a versatile repeat range. This advanced automation minimizes downtime, reduces changeover times, and delivers high-quality graphics profitably for both short and long runs. The S1’s automation technology enhances productivity, reduces waste, and improves print quality, making operations less dependent on highly skilled operators. It also enables label converters to diversify into new growth markets such as sleeves, wrap-around labels, pouches, and sachets.

Key Features:

- Full Servo Control: Shaftless full servo system ensures excellent register accuracy throughout the speed range.

- Electronic Pre-Register: Sensor-based system sets all print units to their correct home positions without material waste, facilitating quick and accurate job setups.

- Electronic Final Register: Each print unit features a Human-Machine Interface (HMI) for register settings, which can also be adjusted from the end-of-press HMI.

- Open Access Design: Provides a clean and clear view of the print unit for quick and efficient job changes.

- Quick-Change Print Cylinder: “No rods” design allows for print cylinder changes within seconds, enhancing operational efficiency.

- Consistent Pressure Settings: Eliminates the need to set pressure for every job; one setting accommodates all, simplifying the printing process.

- Chilled Drums: Incorporates a separate chilled drum with UV to enhance gloss levels and provide sufficient time for the ink laydown to settle before curing.

- Short Web Path: Features a web path of just 1.4 meters between print units, reducing material waste and enabling quick setups.

- Rail System for Accessories: Equipped with a rail system to mount cold foil, turnbar, rotary screen, and other accessories movable throughout the press length, enhancing flexibility.

- 24″ Print and Die Repeat: Accommodates print cylinders from 7.5″ to 24″ and allows for large 24″ die repeats, providing versatility in print jobs.

- Modular Construction: Assembled to your specifications to meet your needs, with the ability to add additional modules as your business and market opportunities grow and change.

- Energy-Efficient UV Systems: Energy-saving UV curing systems are mounted on the chill drums, reducing energy consumption.

Specifications:

| Feature | Details |

|---|---|

| Substrate Range | 12 microns – 400 microns (30 GSM – 450 GSM) |

| Max Speed | 180 m/min |

| Web Width | 370 mm / 450 mm / 530 mm |

| Control System | Shaftless full servo |

| Max Roll Capacity | Unwind: 1000 mm Rewind: 800 mm Waste: 750 mm |

| Print Repeat | 7.5” – 24” (9”–24” for 450 mm) in steps of 1/8” |

| Web Path Distance Between Prints (UV) | 1.5 m |

| Pre-Registration | Standard |

| Auto-Registration | Optional |

| Remote Diagnostics | Standard |

| Job Storage | Standard |

The Multitec S1’s combination of advanced servo technology, user-friendly design, and versatile capabilities makes it an ideal choice for businesses aiming to enhance their printing operations and explore new market opportunities.