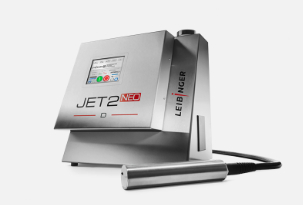

Leibinger JET2 Neo D Continuous Inkjet Printer

Description

The LEIBINGER JET2 NEO D is a dust-resistant CIJ printer designed for challenging environments like flour mills and timber yards. With features like Sealtronic technology to prevent ink drying, a positive air pressure system for dust-free printing, and speeds up to 268 meters per minute, it ensures reliable, high-quality marking on various materials. Ideal for industries needing precision and durability in dusty conditions.

Categories: Continuous Inkjet Printers, Leibinger

Product Details

The LEIBINGER JET2 NEO D is a mid-range Continuous Inkjet (CIJ) printer specifically engineered to excel in dusty production environments, such as flour mills, timber yards, and facilities where airborne particles pose challenges to standard printing equipment. Building upon the robust features of the standard JET2 NEO, the JET2 NEO D incorporates specialized enhancements to ensure reliable and high-quality printing even under challenging conditions.

Key Features:

- Dust-Resistant Design:

- Sealed Back Panel and Housing Ventilation: The printer’s back panel is sealed to prevent dust and particles from infiltrating the internal components. Additionally, active housing ventilation ensures that the electronics remain protected from dust accumulation, thereby enhancing the printer’s longevity and reliability.

- Printhead Air Pressure Innovation: A positive air pressure system within the printhead prevents dust interference during printing. This feature ensures accurate and fast printing, even when marking directly onto dusty surfaces, maintaining print quality and reducing downtime.

- High-Speed Printing Capabilities:

- The JET2 NEO D supports printing of up to three lines of fixed and variable data, accommodating various coding requirements such as batch numbers, expiration dates, and barcodes.

- It achieves impressive printing speeds of up to 268 meters per minute. For applications requiring even higher speeds, the optional JET2 NEO S variant can be utilized to reach speeds up to 403 meters per minute, ensuring efficiency in high-volume production lines.

- Sealtronic Print Head Technology:

- LEIBINGER’s patented Sealtronic system prevents ink from drying out by sealing the nozzle and ink circuit airtight during pauses in printing. This innovation eliminates clogging, reduces the need for frequent print head cleaning, and ensures immediate start-ups with consistent high-quality printing.

- Operational Efficiency:

- Designed with efficiency in mind, the JET2 NEO D helps control operating costs through reduced solvent consumption and energy-efficient operation. This focus on efficiency not only lowers expenses but also supports sustainable practices within industrial operations.

- Versatile Material Compatibility:

- The printer is capable of marking on a wide range of materials, including glass, carton, film, foils, plastics, metal, wire, rubber, paper, textiles, ceramic, and wood. This versatility makes it suitable for diverse industrial applications, ensuring clear and durable markings across various substrates.

- User-Friendly Interface and Integration:

- Equipped with an intuitive interface, the JET2 NEO D allows for easy operation and quick job setup.

- It offers a range of functions and interfaces to integrate seamlessly into existing production environments, providing flexibility and adaptability to various industrial processes.

Technical Specifications:

- Printing Speed: Up to 268 meters per minute (optional upgrade to 403 meters per minute with JET2 NEO S variant).

- Print Lines: Supports up to three lines of text, numbers, or symbols.

- Nozzle Size: Standard 70 µm; optional 60 µm nozzle available with JET2 NEO S variant for finer printing.

- Protection Class: IP54-rated, indicating protection against dust ingress and water spray from any direction.

- Ink Types: Compatible with a variety of inks tailored to specific applications and material requirements.

- Power Supply: 100-240 V, 50-60 Hz, max. 40 VA.

- Operating Temperature Range: +41°F to +113°F (+5°C to +45°C).

- Compressed Air Requirements: Consumption of 23 liters per minute (0.8 cubic feet) with a required inlet pressure of 20.3 PSI.

The LEIBINGER JET2 NEO D is an ideal solution for industries where dust and airborne particles are prevalent, ensuring uninterrupted productivity and superior print quality. Its combination of dust-resistant features, high-speed capabilities, and operational efficiency makes it a valuable asset for businesses aiming to maintain high standards of coding and marking in challenging environments.